During more than a decade of working with manufacturing companies – from mechanical, electronic to food plants – I always saw the same problem over and over again: the lack of synchronization in operational data. A factory can operate dozens of production lines, but if information from the warehouse, planning, QA/QC and accounting does not match, everything will be like managing “in the fog”.

For manufacturing companies, the need for data integration becomes even more vital. A production line has a tight connection between BOM (production standards), raw materials, labor, machinery, quality plans, costs and delivery. Just a small deviation in any link can cause the whole chain to “freeze”. CEO of Toyota Production System – Taiichi Ohno – once emphasized: “Without data, you are just an opinion.” ERP is a system that turns “views” into “truths” with precise numbers

1. What is the Manufacturing Module?

1.1. Definition and Core Position

The Manufacturing Module is a specialized functional subsystem in the Enterprise Resource Planning (ERP) architecture. Structurally, it acts as the Central Operational Hub, responsible for integrating and automating the entire cycle from input planning to output production.

In the ERP model, while modules such as Finance act as the System of Record and Customer Relationship Management (CRM) as the System of Engagement, the Manufacturing Module is the Core Execution System, where resources are converted into final value.

1.2. Main Business Functions

The Manufacturing Module is designed to cover the following technical and management functions:

A. Material Requirements Planning (MRP)

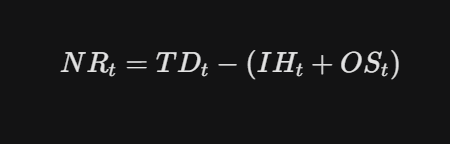

This function uses algorithms to calculate the raw material demand (NRt) and components required for production in a period of time (t).

In which:

- TDt: Total Demand from orders and forecasts

- IHt: Inventory on Hand.

- OSt: On Order Stock.

MRP ensures an optimal balance between inventory levels and order fulfillment.

B. Bill of Materials (BOM) Management

BOM is a hierarchical data structure that accurately quantifies the raw materials, components, and semi-finished products required to produce a unit of final product. BOM is the foundation for Standard Costing and consumables control.

C. Work Order Management (WO)

The module manages the lifecycle of a work order, from release to completion. It tracks cycle time, records actual consumption, and collects data on direct labor at each workstation.

D. Capacity Planning

This function evaluates and allocates production resources (machines, workers) based on projected demand. It helps identify bottlenecks in the process and optimizes the Capacity Utilization Rate.

E. Product Costing

The module automatically aggregates raw material costs, labor costs, and overhead costs to determine the total cost and unit cost. This is the basis for analyzing the Cost Variance between standard and actual costs.

1.3. Strategic Importance

The Manufacturing module is the key to data consistency and traceability throughout the supply chain. By tightly integrating with the Warehouse, Purchasing, and Accounting modules, it ensures:

- Real-time data synchronization: Production information is updated immediately to the accounting ledger.

- Improves OEE (Overall Equipment Effectiveness): By providing data on downtime, scrap rates, and operational efficiency

2. What is MRP? Why is MRP important to the factory?

MRP (Material Requirements Planning) is a core tool that helps businesses determine how much raw materials to buy, when to buy them, and when to produce them. This is based on a combination of three data: orders, actual inventory, and BOM. Without MRP, production planning is often subjective, depending on the Planner's personal experience. Then, the line is prone to shortages of raw materials, forcing workers to wait for work, or, conversely, buying too much, leading to increased inventory and large storage costs.

The operating mechanism of MRP is based on the Backward Scheduling Principle, where production needs are determined from independent demand (customer orders) and calculated backwards over time to determine the exact time to order or produce components.

The three main input data sources for MRP are called The Three Legs of MRP:

- Total Production Schedule Master Production Schedule (MPS): Determines which products need to be produced, in what quantities, and when.

- Bill of Materials (BOM): Provides a hierarchical structure and precise quantity standards of components needed for each product.

- Inventory Records File: Details of current inventory, on-order inventory, and allocated shipments.

According to APICS, businesses that apply MRP can reduce inventory by 20–40% and improve on-time delivery (OTD) by 30%. This thinking was summarized by Intel CEO Andy Grove in a famous quote: “You can’t manage what you don’t measure.” And MRP is the foundation for measuring, thereby managing production scientifically.

3. What is a Work Order? Why is it necessary to track it in real time?

Work Orders are the foundation of every factory's operations, as they fully describe the products to be produced, the processes to be followed, the resources to be mobilized such as labor - machinery - time, and the standards to evaluate completion. In the traditional model, Work Orders are often printed on paper or recorded manually, making information easily misleading, data updates slow, and it is very difficult to trace the cause when problems arise in the chain.

When the factory switches to ERP, Work Orders are monitored in real time, allowing businesses to clearly see which stages are operating, which stages are stuck, compare actual time with standard time, and measure the productivity of each machine, each worker, or each production shift. Siemens' "Digital Factory 2024" report shows that factories applying digital Work Orders can increase OEE performance by 15–25%, thanks to reduced waiting time, reduced communication errors, and increased accuracy in scheduling.

Former Siemens CEO Joe Kaeser once asserted: “A smart factory is not just about automation – it needs transparency.” It is the digitized Work Order in ERP that creates that transparency, helping the factory operate based on data instead of guesswork.

4. Costing – What is production costing?

In manufacturing, production costs become a vital factor that determines the profit margin and scalability of the business. To manage costs scientifically, accurately and promptly, factories are strongly shifting from traditional costing methods to the real-time costing model – where production data is recorded instantly and converted directly into financial indicators. This shift is not just a technology trend, but has been proven by quantitative and empirical research in the manufacturing industry.

From an academic perspective, costing is defined as a set of accounting and analytical methods to determine the full cost of a product, including direct costs (raw materials, labor), operating costs (machine hours, energy) and indirect costs (depreciation, maintenance, overhead). Harvard Business School views costing as the process of converting operation-level data into measurable financial quantities, serving pricing, planning and optimization. This is the foundation of cost accounting and a pillar in all modern production management models.

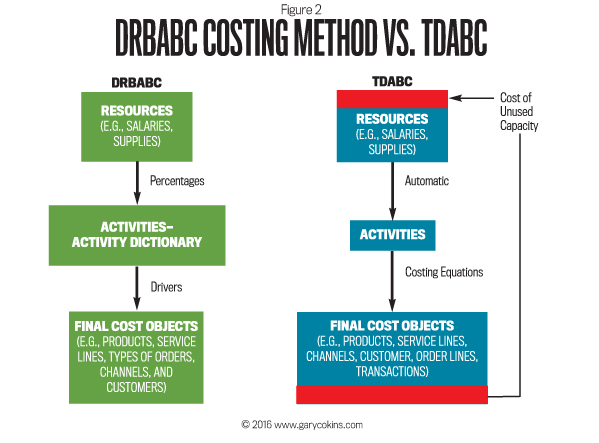

However, traditional methods – which rely on allocation by machine hours or labor hours – are exposing two serious weaknesses. First is the lag, when businesses only calculate costs at the end of the period, making them unable to detect fluctuations in material consumption, scrap rates or productivity. The second is allocation distortion, when products of different complexity are allocated the same simple driver, causing cost distortions of up to tens of percent. Many overview studies have shown a large level of “cost distortion” for factories with high product diversity when using traditional methods, leading to management-level decision-making based on inaccurate data.

To overcome the above limitations, advanced factories apply modern methods such as Activity-Based Costing (ABC) and especially Time-Driven Activity-Based Costing (TD-ABC). The TD-ABC model, developed and popularized by Harvard Business School research, uses activity execution time as the central cost driver, making the model both simpler and more accurate. When combined with data from MES, IIoT and sensor systems in the factory, TD-ABC becomes the natural foundation of real-time costing.

Real-time costing is not just a costing method, but also a new data architecture: machines and equipment are continuously connected, recording cycle times, material consumption, scrap rates, and actual performance. When this data is fed into an ERP or digital twin of the production line, businesses can forecast unit costs as soon as there are changes in productivity or equipment behavior. A study on “real-time product cost measurement” on the IDEAS/RePEc platform has demonstrated that using real-time machine hour data helps cost models get closer to real costs, especially in a highly variable manufacturing environment.

These research findings are supported by real-world case studies. McKinsey notes that a factory that has undergone a comprehensive digital transformation has reduced product costs by more than 30% through increased OEE, optimized machine capacity, and reduced scrap – direct benefits of real-time analytics. Deloitte also reports that predictive maintenance helps businesses reduce maintenance costs by 5–10% and increase equipment availability by 10–20% – factors that contribute to lower unit costs. At the same time, smart factory studies show that increasing OEE by 5–15% can shift manufacturing costs down significantly, especially in high fixed-cost lines.

What makes real-time costing effective is the mechanism that directly impacts costs. When anomalies are detected immediately – such as reduced productivity, increased scrap, or machines running beyond standard time – businesses can intervene immediately to prevent losses from spreading. Using granular drivers such as machine hours per shift, processing time per stage, and material consumption per batch helps allocate costs more accurately, avoiding the situation where simple products “bear” the costs of complex products. Integrated MRP also supports inventory reduction, optimizing purchasing chains, and reducing warehousing costs. All of this creates a system where every small deviation is seen, measured, and handled before it turns into a large cost.

To implement real-time costing according to research standards, factories often follow a verifiable experimental path: standardizing KPIs (unit cost, yield, scrap rate, OEE, etc.), verifying the quality of source data, designing TD-ABC models, connecting MES and sensor data, deploying 4–8-week parallel pilots, and evaluating standard-real variance. Each stage requires a clear hypothesis and specific measurements to verify, in line with the spirit of empirical research: “speak with data, not with feelings”.

Of course, real-time costing also brings challenges. The quality of source data is vital; wrong data will lead to wrong decisions. The investment costs for MES, IIoT and integration are not small, requiring businesses to calculate clear ROI. Real-time costing models can become complicated without proper governance. And finally, real-time data can change human behavior if the KPI system is not carefully designed.

Case studies like McKinsey’s show that production costs can be reduced by tens of percent under the right conditions, while Deloitte’s quantitative benefits on predictive maintenance contribute to strengthening overall efficiency. However, the final efficiency always depends on the quality of data, implementation roadmap and the business’s own change management capacity.

5. What is QA/QC in ERP?

QA (Quality Assurance) and QC (Quality Control) have long been considered two inseparable pillars in the quality management system of any factory. If QA is a preventive “shield”, responsible for building processes, standards and working methods to prevent errors from the beginning, QC is a “key point” of control, ensuring that each product or semi-finished product is checked at important stages before moving to the next stage or before leaving the factory. When applied manually, QA/QC is often separated from actual operations — processes are on paper, reports are in Excel files and error information only appears when the product has gone too far in the chain.

The difference appears when businesses integrate QA and QC directly into ERP or MES. Quality checkpoints are then embedded in the production flow: each step, each production order, even each batch of raw materials can be checked using a checklist or quantitative criteria. All defect data — including the type of defect, the equipment causing the defect, the operator, the time of occurrence, and the machine condition — is recorded in real time. This allows managers to trace back precisely: which batch of raw materials, which machine, which shift, and whether the defect is due to a process or human error. ERP not only records, but also connects the defect to the BOM, Routing, Work Order, Warehouse Lot, and even the rework cost, creating a comprehensive quality map.

This instant transparency has a big impact in practice. At a plastics factory where I implemented ERP, real-time QA/QC integration reduced the defect rate from 5% to just 0.5% after 6 months. There’s no complicated secret sauce — simply spot-on detection, faster root cause analysis (RCA), and automatic updates to the prevention process. When any unusual trends like off-spec finished product thickness, increased burrs, or unusual machine vibrations are detected, the system alerts before the problem spreads. Each early detection translates to hundreds or thousands of fewer defective products on the line.

This philosophy is perfectly aligned with quality guru Philip Crosby’s famous quote: “Quality is free — because it’s always cheaper than repair.” When an ERP system is implemented correctly, this statement becomes a truism. The cost of preventing errors at the source is always less than the cost of fixing errors, rejecting products, handling complaints, or losing customers. ERP — through integrated QA/QC — shifts quality from “reactive” to “preventive and proactive,” helping factories operate more accurately, with less waste, and produce consistent products at lower costs.

6. Why is the manufacturing module a strategic investment?

The Manufacturing module is considered one of the most strategic investments in the digital transformation of manufacturing enterprises, because it directly impacts operational efficiency, costs, and long-term competitiveness. Many businesses mistakenly believe that production advantages come from robots, automated lines, or expensive machinery. However, McKinsey’s survey in the field of smart manufacturing shows that the biggest factor in improving factory performance is not the equipment, but the level of connectivity and Data transparency. No matter how modern the machinery is, it cannot achieve optimal efficiency if the information between departments is broken. When the warehouse does not know the production plan, raw materials may be lacking or surplus; when the planning department does not know the actual machine capacity, the production schedule will be incorrect; when QA cannot trace errors from any stage, the business cannot reduce waste; and when accountants do not know the cost of consumption at each step, cost control is almost blind.

This situation shows that the Production module is not just a management software, but a platform that helps businesses operate based on real data instead of emotions. This is also the spirit of the famous warning of Jack Welch - former Chairman of General Electric: "An organization that does not learn to use data will be left behind." This statement clearly reflects the new landscape of manufacturing: where speed, accuracy, and responsiveness are no longer dependent on human effort, but on how effectively data is created, linked, and used across the entire supply chain.

When a company fully implements the Manufacturing module in ERP, data from BOM, MRP, Work Order, QA/QC, maintenance, warehouse, and finance are consolidated into a single flow. As a result, the factory can forecast capacity, optimize planning, reduce inventory, control errors in real time, and calculate the correct cost of each product. In other words, the Manufacturing module is the area that generates the clearest ROI in the entire ERP system — because it targets the biggest loss points of the factory: lead time, production interruptions, excess inventory, scrap, and hidden costs.

Therefore, investing in the Manufacturing module is not a simple technology project, but a strategic decision that shapes how competitive businesses in the next 5–10 years. Businesses that build data-driven management capabilities will operate faster, more accurately, and more efficiently — while others will gradually fall behind, just as Jack Welch once predicted.

7. Conclusion

The manufacturing market today operates faster than ever: orders are shorter, customer requirements are more stringent, and profit margins are getting thinner. Businesses that know how to use data to optimize production will lead, while those that operate manually will quickly be left behind.

The Manufacturing module in ERP is the key for businesses to reduce costs, increase speed, improve quality, and enhance competitive advantage. As Bill Gates once said: “Technology is what amplifies human capabilities.” ERP, and especially the manufacturing module, is the tool that amplifies the operational capabilities of the entire business.